Concept

Features:

- Position Detection

- Shape Surveillance

- Motion Analysis

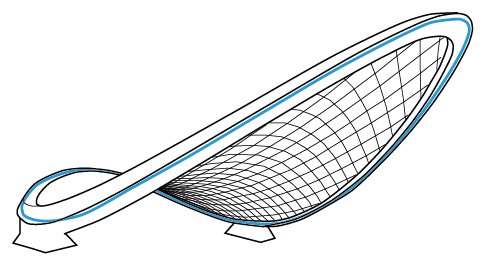

The "Shape-Sensor for Large Objects" enables the detection of shape forming and position of an elongated object. Therefore a model is build, that follows the movements of the object in real-time. The detection works with high precision, allowing shape modelling over several hundred meters.

The shape information may be used for control tasks. The change of an object over time can be observed. Oscillations can be detected. Critical shape arrangements may be detected and stress analyses are feasible.

Function

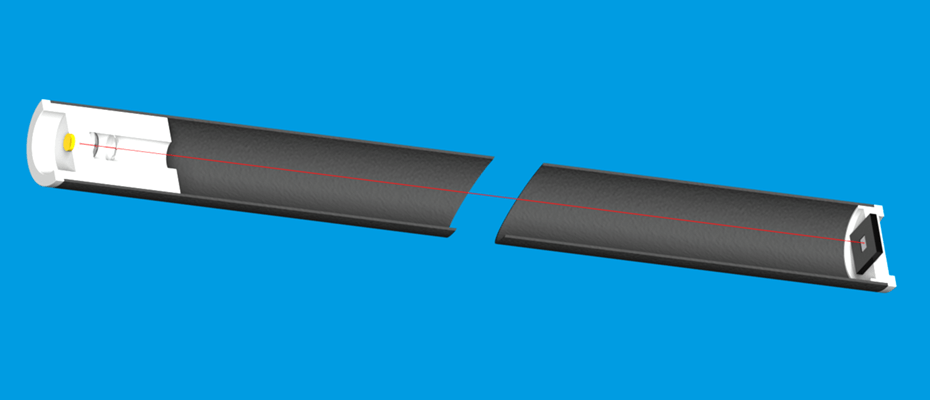

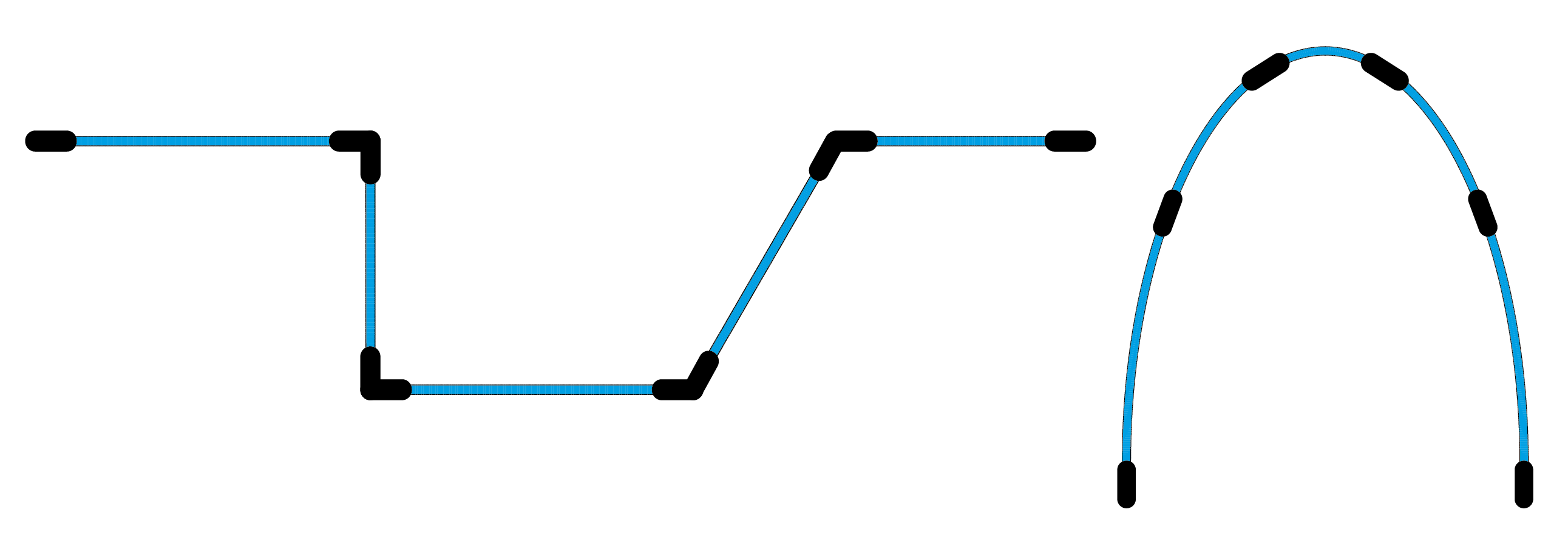

The sensing of shapes is accomplished by laser measuring sections integrated in tubes. The tubes can be connected to one another, so that for each application a suitable system can be configured. A special realization allows not only the detection of bending but also torsion. The configuration of the tubes is extendable, allowing the measurement of accelerations, gyro, magnetic field and pressure.

The tubes have a diameter of 75mm and a range of length from 2-6m.

The sequential arrangement of the sensor segments is detected automatically and a corresponding three-dimensional model is created. The segments may be connected by angle pieces to fit the objects shape. The flexibility of the complete sensor system can be adapted by variation of the segment length.

Possible Applications

For typical applications, the position and orientation at the sensor end are detected.

For some applications, the current shape forming ist relevant too.

For all applications a concurrent monitoring can be realized: If a part of the sensor-array reaches a critical position. If a sensor assumes a critical shape. If parts of the cable approach critical velocities.

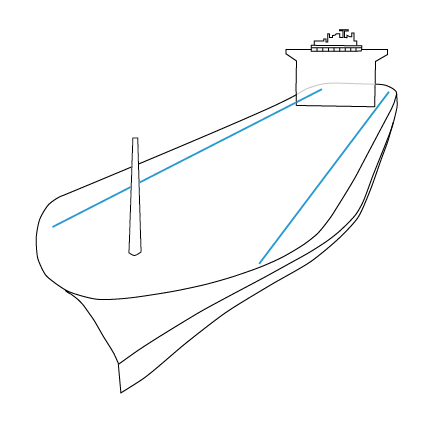

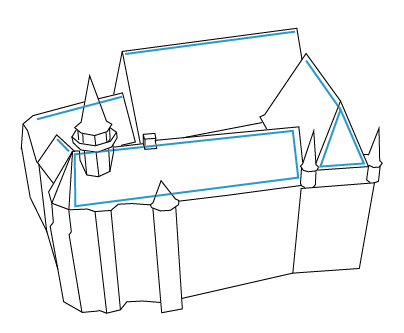

Large technical facilities like ships, cranes or machine beds may be monitored. Fatigue of material and overload is detectable. Maintenance intervals may be prolonged. Control may be improved. For ship hulls, it is possible to detect deflection and torsion in heavy sea, but also in loading situations, especially for bulk cargo ships.

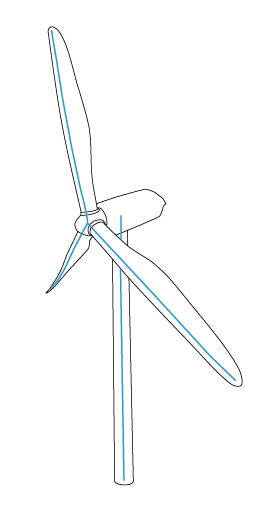

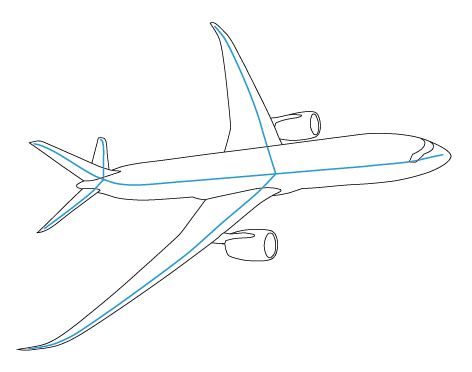

Deformation and properties of air flow may be detected and optimized. The detection of critical situations can be established robust and quickly.

For wind turbines, deflections are only detected dotwise or only parts of a blade are observed because of optical occlusion given by deflection. With the "Shape-Sensor for Large Objects" it is not only possible to detect the deflection, but also the complete three-dimensional bending line and torsion of the blade. This is important for new wind turbines, which realize a fast blade control. The plant is able to react more precise of current wind distributions and the whole system can be load driven. Even the compensation of local gusts and of the shadowing around the tower can be realized with high precision. The detection of ice on the blade and structural damages is possible too.

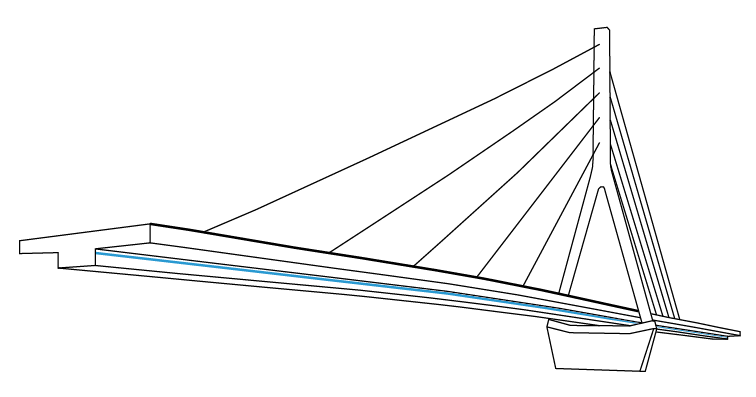

For bridges a permanent surveillance and stress analysis can be realized. Monitoring can be done remotely, enabling central condition monitoring for this buildings. Inspection activities can be conducted more target-oriented. Maintenance costs can be reduced.

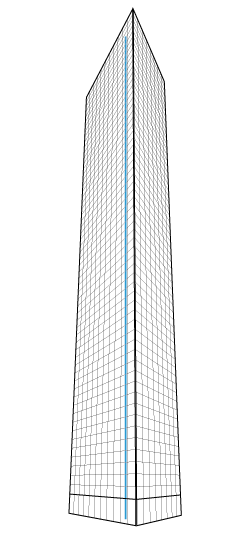

Buildings can be surveilled. The detection of wind load or seismic influences is feasible. The deformation of building corpus is measurable. This is often critical for historical buildings. For high rise buildings, the sensor system may be easily installed in an elevator shaft.